Understanding Concrete Batching Plants and Their Components

Concrete batching plants are essential facilities in the construction industry, designed to produce ready-mixed concrete with high quality and consistency. This article provides an overview of the components and functions of concrete batching plants, their benefits, and considerations for selecting the right plant.

Benefits of Concrete Batching Plants

Concrete batching plants automate the mixing process of raw materials—such as crushed stone, sand, water, and cement—ensuring that they are combined in precise proportions. This automation leads to several advantages:

- Increased Productivity: Automated processes significantly speed up production compared to traditional manual methods.

- Consistent Quality: The precision in mixing results in uniform concrete quality, which is crucial for construction integrity.

- Reduced Labor Costs: Automation minimizes the need for manual labor, leading to cost savings.

Main Components of a Concrete Batching Plant

- Aggregate Hopper: Stores various aggregates like sand and gravel, ensuring continuous feeding into the mixing process.

- Aggregate Weighing Conveyor: Transports aggregates from the hopper to the mixer, where accurate weighing is critical for quality control.

- Aggregate Transfer Conveyor: Moves weighed aggregates to the mixer; its design varies based on plant capacity.

- Weigh Hoppers for Cement, Water, and Additives: Accurately measure these ingredients using advanced sensors and PLC systems.

- Concrete Mixer: The heart of the plant that combines all ingredients into homogeneous concrete. Types include:

- Pan Mixers: Ideal for small to medium batches.

- Planetary Mixers: Suitable for high-performance concrete production.

- Twin Shaft Mixers: Efficient for large-scale projects.

- Cement Silos: Store cement in a controlled environment to prevent quality deterioration.

- Screw Conveyor: Transports cement from silos to mixers accurately.

- Air Compressor: Supplies compressed air for various pneumatic operations within the plant.

- Control Room and Software: Centralized system for monitoring and managing plant operations.

- Valves, Pistons, and Motors: Regulate material flow and ensure precise operation of various components.

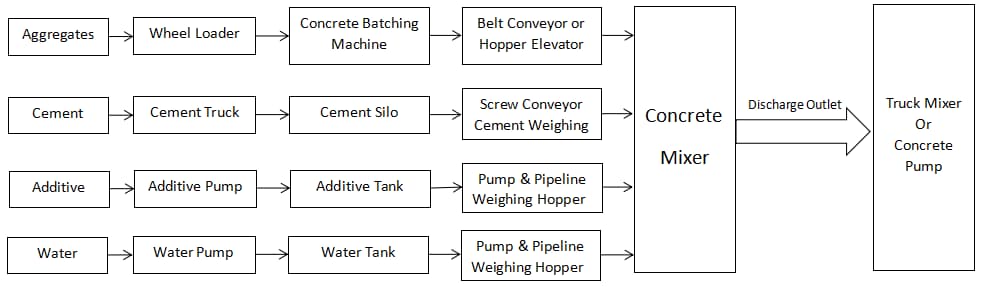

Working Principle

The operation of a concrete batching plant follows a systematic workflow:

- Batching: Raw materials are weighed according to project specifications.

- Conveying: Weighed materials are fed into the mixer.

- Mixing: Ingredients are thoroughly mixed to achieve uniformity.

- Discharge: The mixed concrete is discharged and transported to the construction site.

Types of Concrete Batching Plants

Concrete batching plants can be classified based on their design and application:

- Fixed Concrete Batching Plants: Used for large-scale projects with high production capacities; they offer efficiency but require professional installation and dismantling.

- Mobile Concrete Batching Plants: Designed for flexibility and portability; suitable for smaller projects or sites requiring frequent relocation.

- Commercial Concrete Batching Plants: Focused on producing concrete for sale; they emphasize high automation and quality control.

Choosing the Right Concrete Mixing Plant

When selecting a concrete batching plant, consider the following factors:

- Quality of Equipment: Ensures long-term reliability.

- Regular Maintenance Needs: Extends equipment lifespan and maintains efficiency.

- Calibration Accuracy: Critical for ensuring quality concrete production.

- Professional Support: Opt for manufacturers that provide comprehensive technical assistance.

Conclusion

Concrete batching plants play a pivotal role in enhancing construction efficiency and quality. By understanding their components and operational principles, users can make informed decisions when selecting or maintaining these facilities. A high-quality batching plant not only boosts productivity but also guarantees consistent concrete quality essential for successful construction projects. Regular maintenance and precise calibration further ensure that these plants operate smoothly over time, delivering reliable results in various construction applications.

评论

发表评论