How does a concrete batch plant work?

A concrete batching plant, also known as a concrete plant, is essential for producing high-quality concrete efficiently. This sophisticated equipment mixes aggregates, sand, cement, water, and various additives in precise proportions to ensure consistent quality. The advent of concrete batching plants has significantly enhanced both the efficiency and quality of concrete production.

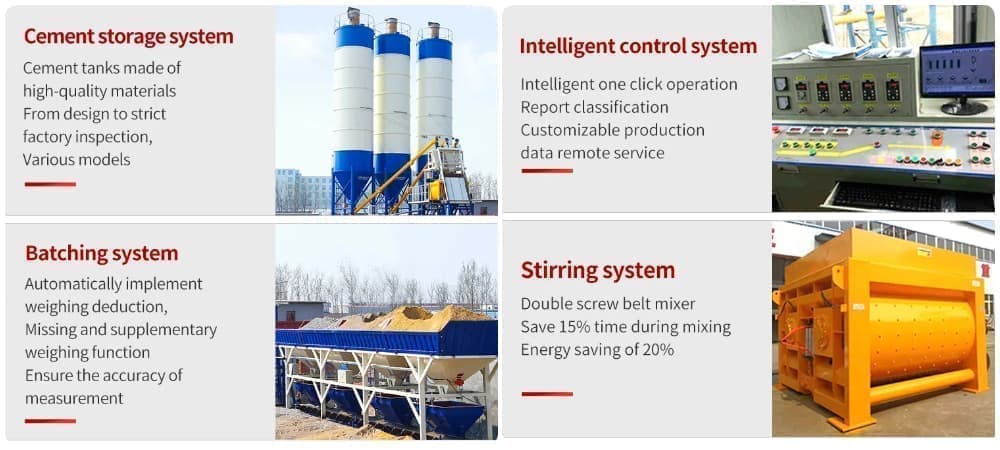

Components of a Concrete Batching Plant

To grasp how a concrete mixing plant operates, it's crucial to understand its main components:

Aggregate Batching System: Comprising aggregate silos, weighing devices, and conveyor belts. Aggregate bins store different sizes of aggregates, while weighing devices accurately measure their weight before they are fed into the mixer.

Powder Batching System: This includes silos for cement, fly ash, and admixtures, along with weighing devices and conveyors for storing and measuring powdered materials.

Water Dosage System: Consists of a water tank, pump, and weighing device to store and deliver the required amount of water based on the concrete recipe.

Mixing System: The mixer is the core component where all materials are combined to create concrete. Common types include double horizontal shaft forced mixers and self-falling mixers.

Control System: This is the nerve center of the plant, managing the operation of all equipment and ensuring accurate concrete proportioning.

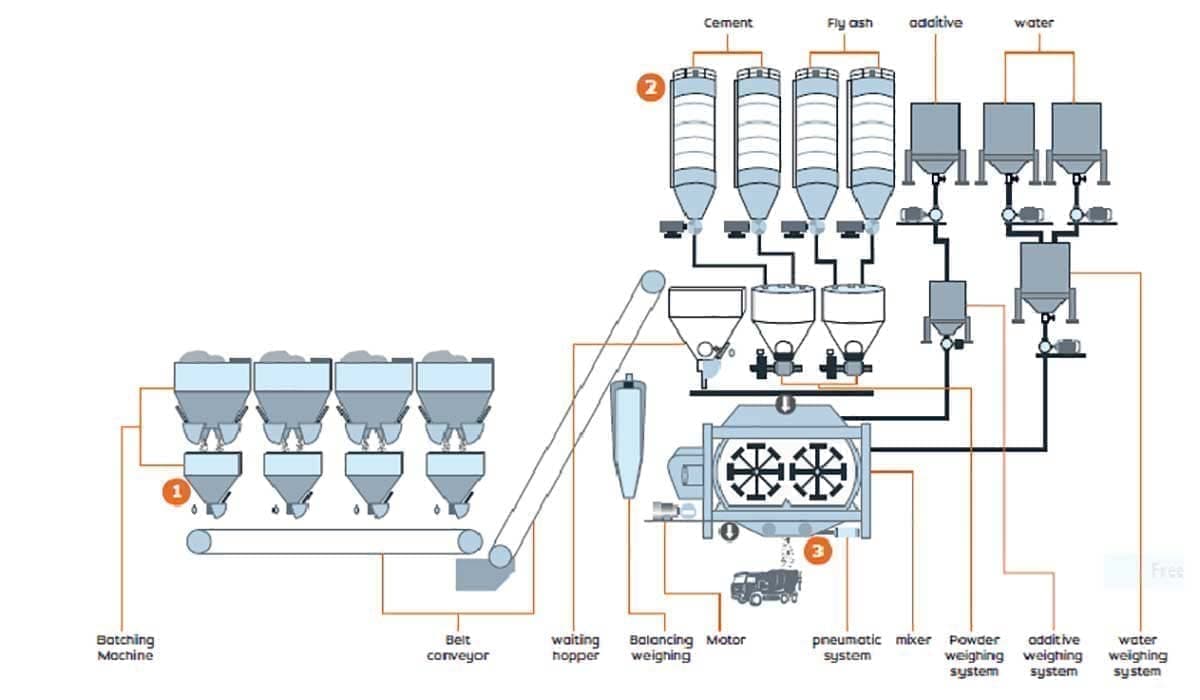

Working Principle and Process

Concrete mixing plants can be categorized into fixed and mobile types. Fixed plants are larger and suited for long-term projects, while mobile plants offer flexibility for smaller projects with changing sites. Regardless of type, their working principle involves several key functions:

Aggregate Supply: Aggregates are stored in separate silos based on grain size.

Powder Supply: Storage and conveyance of powdered materials like cement and fly ash.

Water Supply: Accurate measurement and delivery of water as per the recipe.

Additives Supply: Addition of various additives to enhance concrete performance.

Mixing: Weighed materials are combined in the mixer to form uniform concrete.

The production process begins with weighing aggregates according to a preset formula. After weighing, materials enter the mixer for thorough mixing before being discharged into transport vehicles or pumping equipment for delivery to construction sites.

Application of Concrete Batching Plants

Concrete batching plants are widely utilized across various construction sectors:

High-Rise Buildings: They supply high-quality concrete for structural components like floor slabs and columns.

Roads and Bridges: Concrete produced is essential for paving roads and constructing piers.

The ability to produce ready-mixed concrete through precise formulas meets modern construction demands for quality and efficiency. Technological advancements in control systems have further automated these processes, enhancing production efficiency and product consistency.

Frequently Asked Questions

How do you prepare different grades or qualities of concrete?

The grade depends on the proportion of constituent materials, mixing ratios, methods, and curing conditions. Adjusting these factors allows for tailored concrete production.

What factors affect the grade and quality of concrete?

Key factors include:

- Cement varieties and dosage

- Aggregate properties

- Water-cement ratio

- Use of admixtures

- Mixing time and method

Curing conditions

What are the common types of concrete batching plants?

- Dry Mix Concrete Plants: Components are dried before being mixed with water during transport.

Wet Mix Concrete Plants: All ingredients are mixed before being transported, ensuring a more consistent product.

What types of mixers are used in batching plants?

- Common mixer types include:

- Reversible drum mixers

- Twin-shaft mixers

- Single shaft mixers

- Planetary mixers

- Disc mixers

- Common mixer types include:

Each mixer type serves specific production needs, allowing flexibility in meeting varying project requirements.

In summary, concrete batching plants play a vital role in modern construction by producing high-quality concrete efficiently through advanced technology and precise processes.

评论

发表评论