6 Types of Batching Plants You Need to Know

Concrete mixing plants are essential mechanical systems designed to efficiently produce large quantities of concrete, playing a vital role in modern construction projects. These plants enhance construction efficiency, minimize material waste, and reduce costs by mixing concrete in precise proportions. Various types of concrete mixing plants cater to different project requirements, ensuring that construction needs are met effectively.

Types of Concrete Mixing Plants

Concrete mixing plants can be categorized into six common types, each with unique features and applications:

1. Stationary Concrete Batching Plant

Stationary concrete batching plants are large-scale facilities permanently installed at a specific location. They are equipped with mixers, aggregate silos, cement silos, and conveyor belts, often featuring automated control systems for stable production. These plants are ideal for long-term projects requiring consistent concrete supply and come in various capacities ranging from 60 to 240 m³/h.

2. Mobile Batching Plant

Mobile batching plants offer portability, allowing them to be relocated easily as project needs change. Mounted on trailers, these plants can produce between 25 to 120 m³ of concrete per hour. Their quick installation and minimal infrastructure requirements make them suitable for medium and small-scale projects.

3. Foundationless Concrete Batching Plant

Foundationless concrete batching plants require no special foundation, making them easy to set up on level surfaces. They are compact and perfect for short-term projects such as road and bridge construction. Key advantages include rapid installation, low transport costs, and efficient production capabilities.

4. Centralised Concrete Batching Plant

Centralised mixing plants consolidate all raw materials in one mixer, offering high productivity and consistent quality. Ideal for precast production and commercial supply, these plants ensure uniformity by thoroughly mixing components before transporting the concrete to construction sites.

5. Ready Mix Concrete Batching Plant

Ready Mix Concrete (RMC) batching plants produce concrete tailored to specific job requirements. They automate the mixing process to ensure consistency and quality, making them suitable for large-scale construction and municipal engineering projects.

6. Dry Concrete Batching Plant

Dry concrete batching plants mix aggregate materials without water until they reach the construction site, where water is added during transport. This method reduces water evaporation and maintains stable quality but requires on-site mixing capabilities.

Comparison of Concrete Mixing Plants

| Type | Advantages | Disadvantages | Applicable Scope |

|---|---|---|---|

| Centralized | High production efficiency, stable quality | Large area required, higher investment | Large-scale construction projects, precast component production |

| Ready-mixed | Quality assured, convenient for construction | Higher cost | Large-scale construction projects, municipal engineering |

| Dry mix | Reduced water evaporation, stable quality | Requires on-site water mixing | Projects with limited construction site space |

| Mobile | High flexibility, small footprint | Limited production capacity | Medium and small-scale construction projects, temporary projects |

| Stationary | Large production capacity, fully equipped | Poor flexibility | Large-scale construction projects, commercial concrete production |

| Continuous | High production efficiency | Higher investment | Large-scale concrete production projects |

Impact of Mixing Plant Choice on Project Quality

Choosing the right concrete mixing plant significantly influences the overall quality of construction projects. Key factors include:

- Production Capacity: The plant must meet project demands; insufficient capacity can delay progress.

- Consistency and Quality Control: Advanced technology ensures uniformity in concrete quality.

- Quality of Raw Materials: Effective procurement channels enhance the strength and durability of the final product.

- Management Mechanism: A robust management system ensures compliance with quality standards throughout production.

- Environmental Factors: Proximity to the construction site affects transport time and costs.

Conclusion

Selecting an appropriate concrete mixing plant is crucial for enhancing construction efficiency while ensuring high-quality output. Each type of plant has distinct advantages tailored to various project scales and requirements. As technology continues to evolve, the importance of these facilities in the construction industry will only grow.

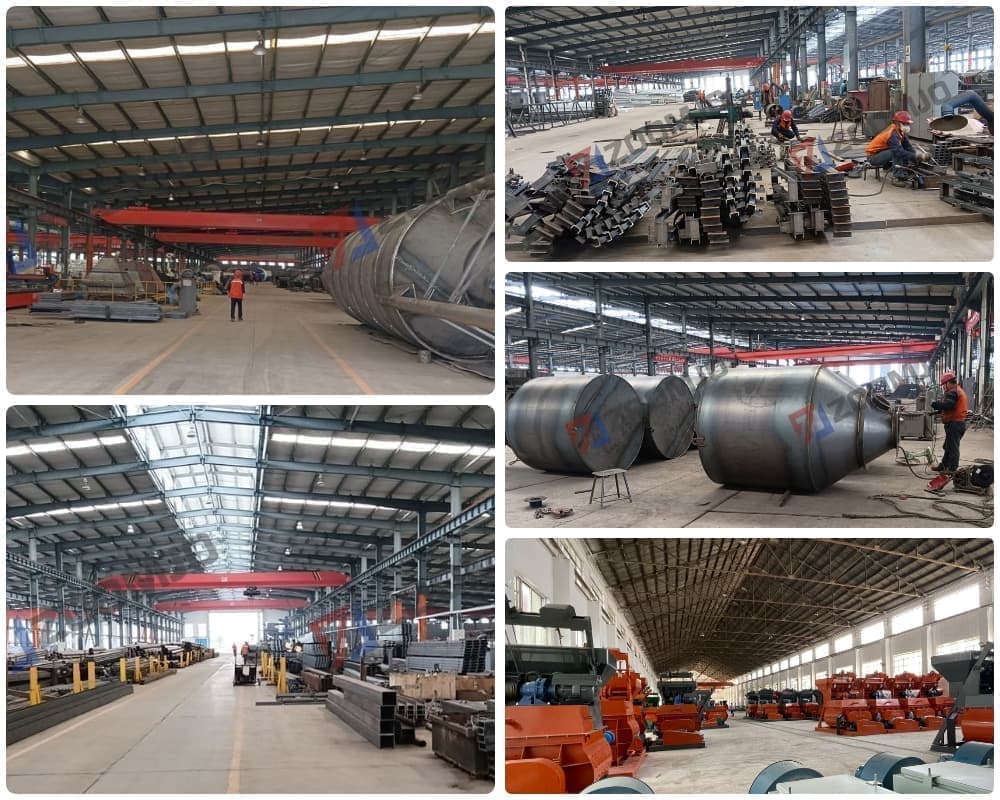

For more information on concrete batching plants or to receive a detailed quotation, consider reaching out to ZOOMJO, a leading manufacturer in China that offers professional advice tailored to your specific needs.

评论

发表评论